The bonds between plastic and rubber are often not so strong because of their dry surface. However, you can still bond these two different materials by following the step-by-step guide on how to glue plastic to rubber.

- Step 1: Surface treatment

- Step 2: Apply glue

- Step 3: Wait for the glue to harden

If you are in doubt, continue reading the article below for details!

Things You’ll Need

The failure of rubber and plastic bonding is mainly due to weak adhesives, non-standard surface treatments, and others. In order not to make the above mistake, prepare all the necessary tools according to the instructions below.

Adhesive

Quite a few glues work well on rubber and plastic surfaces. The three notable types are super glue, silicone-based glue, and two-part epoxy glue.

- Super Glue

It is acrylic based with good performance on rubber and many other surfaces.

Its most significant advantage is that it cures quickly, especially in environments with sufficient humidity.

Yet, this feature has both its advantages and disadvantages. Using this glue, it will be nearly impossible for you to adjust or reposition the material comfortably. You must act quickly in the first few minutes.

- Epoxy resin glue

It is also known as a two-part glue. So, you will have to mix the resin and its hardener in specific proportions.

This glue is quite famous for bonding plastics and rubber because of its ability to create solid and waterproof bonds. You can also use this adhesive mixture to repair and fill gaps.

- Silicone-based adhesive

This type is heat, chemical, and water-resistant to create a flexible bond after curing. Yet, it is often quite slippery when used on rubber and plastic. The trick is that you should apply a primer or surface treatment to increase friction.

Surface treatment supplies

For the glue not to lose its effectiveness on slippery surfaces, you need to use surface treatment tools such as sandpaper, cleaning solution, and primer.

The sandpaper will be very helpful to rub for the glue to work better. Primer is also the ideal tool for extensive surface treatment.

You can also use soap to remove the oil layer on the rubber to avoid slipping.

Protective equipment

Adhesives for everyday use will not be too toxic. But, during the processing, you definitely won’t want glue or dirt on the skin of your hands and clothes.

For more safety, you need some protective equipment such as gloves and masks, and use them throughout the work.

It would help if you also had acetone on hand to clean up glue that’s spilled or stuck to clothing and surfaces.

How To Glue Plastic To Rubber? A Step-By-Step Guide

It is not difficult to create a sustainable bond between plastic and rubber. Here are all the steps you need to take to handle these two unique materials.

Step 1: Surface treatment

Your rubber and plastic surfaces need to be free of grease or impurities.

For plastic or rubber that already has a coating, you need sandpaper to remove this coating before applying the glue.

Using Cyanoacrylate glue, you should prepare an additional CA glue activator. This substance will promote the bonding process to shorten your waiting time.

Most glue activators require an application before the glue is applied to the surface. After removing dirt and excess oil, you can use a layer of activating adhesive on the surface for more stability.

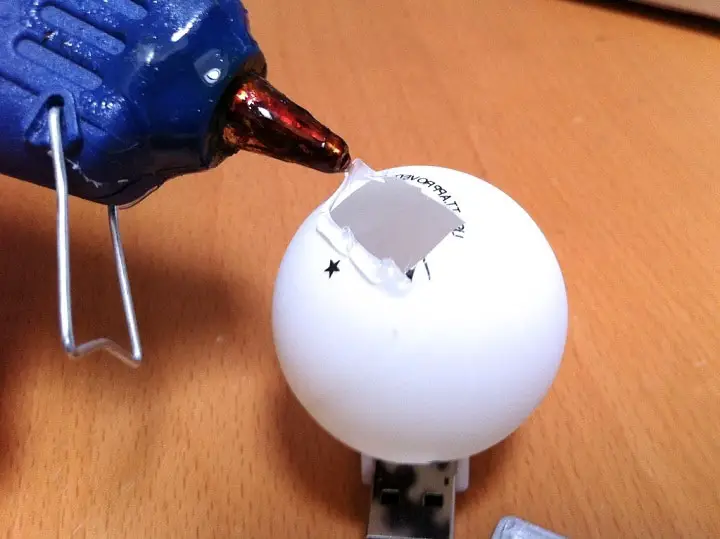

Step 2: Apply glue

After completing the surface treatment steps, you can apply the glue. Typically, the ideal glue density is one drop per square inch.

After applying glue on one surface, coat the other surface on top. Then apply just enough pressure to stick the plastic and rubber together. You should maintain just enough pressure for about 30 seconds for adequate bonding.

Step 3: Wait for the glue to harden

In 30 seconds, the glue will form a bond between the plastic and the rubber. It’s not a permanent link yet.

You have to wait for the adhesive to set for the two materials to stick together.

Each glue has a different time and requirements for curing. Typically, Cyanoacrylate glue will cure best in high-humidity conditions.

Meanwhile, some other adhesives only cure entirely after 24 hours of use.

FAQs

Mounting rubber and plastic are not too complicated. Yet, there are quite a few problems associated with this process. If you are also wondering how to bond two surfaces, here is some information you can refer to.

How fast does glue dry when applied to plastic?

The glue will completely dry after about 10-20 minutes from when it is to the plastic. Yet, it will take about 12-24 hours to cure and form a permanent bond.

The above time may vary depending on the type of glue, the amount of cement, and the temperature and humidity of the area you work.

Will super glue work on plastic and rubber?

Superglue works well on both rubber and plastic. It is the best option for creating sustainable links.

However, its expensive cost probably won’t be optimal for your large-scale project. Consider your budget carefully before deciding to apply this glue.

Does hot glue work on rubber?

Hot glue is compatible with certain rubbers. Yet, it won’t work on high-oil ones or materials containing plasticizers like polypropylene and polyethylene.

Can I glue rubber to PVC?

You can use bonded rubber entirely to PVC by using suitable glue. You must keep the adhesive surface clean and use glue to make a strong connection.

Does silicone stick rubber to plastic?

Silicone-based adhesives well meet the needs of rubber and plastic bonding.

This elastomer adheres to various substrates such as nylon, PPO, polyethylene, and fiberglass.

Conclusion

Hopefully, through the specific instructions above, you have answered the question: How to glue plastic to rubber?

If you carefully prepare the necessary accessories and follow every step I suggest, you should have almost no difficulty handling this task quickly.

If you encounter difficulties during the implementation process, do not hesitate to contact us to receive specific answers.

Thank you for reading!