The best glue for PLA is an excellent tool for “express repair” of products made of polymer materials. Using a special composition, you can quickly and effortlessly eliminate the breakdown at home.

Let’s see what kind of adhesive manufacturers recommend to us and what buyers think. Consumer reviews will help you make your choice.

At Glue Care, you can find five top picks that passed our tests.

Scroll down to see what we have!

Our Top Picks: Best Glue For PLA

Gluing PLA parts together is an art form in and of itself. You may glue PLA components together in various methods, including superglue, epoxy, hot adhesive guns, polyurethane glue, and acetone.

Each of these bonding agents has a particular manner of application and its own set of benefits and drawbacks. This post will focus on Cyanoacrylate adhesive and summarize what we believe is the greatest available product.

| Image | Name | Details |

|

| |

|

| |

|

| |

|

| |

|

|

The Best Glue For PLA Reviews Of 2022

There are numerous methods: some create invisible seams, while conventional adhesives result in a huge and unsightly bulge. Whatever method you use, make sure the treatment areas are smooth.

It will help completely clean the surface with fine sandpaper before applying the adhesive. Sanding is an excellent approach to balance out uneven surfaces.

Each approach has advantages and disadvantages, so it’s essential to consider all of them before deciding which one is ideal for your present job.

1. STARBOND EM-02 Super Fast Thin – Best For Application

Buy on Amazon

Important Specifications

- Net Wt: 2 oz

- Bonds: Wood, PLA

- Color: Clear

Product highlights

We’ve tried a lot of CA glues, and this is by far the simplest and most effective. It’s as thin as water and penetrates the same PLA filament swiftly and thoroughly.

The CA is fantastic as well, so the overall package is fantastic. Furthermore, the amount of genuine adhesive per dollar vastly outnumbered any other brand.

We use a lot less of this adhesive than we have with other glues we’ve tested. This 2-oz bottle will last us a long time and is less expensive than any store-bought brand we’ve tried.

It truly dries quickly, allowing you to complete more work in less time. Thanks to the whip tips, you’ll also have a lot of control over where the adhesive travels.

The ultra-thin adhesive’s extension tips prevent evaporating too quickly, allowing exceptionally accurate distribution and volume to a specific region. Anyone who deals with thin CA understands the significance of location and volume.

You may also apply it on the sanded PLA with a q-tip, which helps you to get it exactly where you want it without it flowing all over the place.

You should store it at 104 degrees Fahrenheit for maximum life. We wouldn’t recommend leaving it anywhere where a child may find it, for obvious reasons.

It is better to store it in the refrigerator to maintain its original properties. Only take it out each time you use it, then put it back in the fridge.

Before using it, put on a pair of nitrile gloves. That proved to be a wise option because the adhesive will certainly cement your fingers together.

We believe we’ve located our one-of-a-kind Thin CA. Once we’ve used up our current supply, we’ll try their medium and thick variants. Any serious RC modelers working with PLA should give this a try.

What We Like

- Liquid

- Fast penetration

- Economical solution

- Instant bond forming

- Dries quickly

- Prevention of evaporating

- Exact distribution

Thing to Consider

- Bonds skin instantly

Bottom line

This instant glue is the best Thin CA we’ve tried so far, and it’s likely to be the one we use solely in the future. Not only is the CA itself wonderful, but the bottle and the three alternative delivery options are equally so.

2. 3D Printer Adhesive Glue – Best For Instant Bond

Buy on Amazon

Important Specifications

- Net Wt: 4 fl oz.

- Bonds: PLA, ABS, PETG, ASA, CPE

- Color: Clear

Product highlights

This product is fantastic and performs admirably. We’ve run multiple designs through our printer using PLA material, and none of them have warped or lifted off the print bed.

It worked well on the first try with our standard 60°C bed temperature, and we didn’t have to learn how to fine-tune it in any way. That initial application probably yielded a dozen prints.

Clean the glass bed again according to Layerneer’s directions on the BedWeld packaging. Using three pieces of paper to establish the nozzle distance during leveling and an even application of BedWeld on the whole bed will assist.

You’ll have practically perfect adherence when it dries. Before it would release, you had to let the bed cool for more than 10 minutes.

We cleaned it off with hot water, dried the glass pane, then applied a new layer when it started to lose its adhesive capabilities in a few locations. It was quick and simple, and it was well worth the work per 10 or so prints.

The instructions recommend using a moist sponge to renew it, but we don’t think that’s required. It will stay a long time in a bottle.

You may use it to decrease warping on PLA pieces prone to warping during the printing process. However, it also performs well in ensuring strong first-layer adhesion for pieces with minute features on the first layer.

The components virtually slip off the hotbed when it cools down after printing. Even huge components covering a substantial portion of the construction plate come loose.

It isn’t a replacement for properly calibrating and leveling your printer, though. Before using it, make sure you read and understand the directions since some materials are incompatible, and heating it too high can harm your print and perhaps your glass build platform.

They recommend using a sponge, but we find that a finger gives me a good even distribution. Apply a little extra now and then as needed.

What We Like

- A very strong bond without PLA solder

- Work flawlessly.

- Heat resistance.

- Stay a long time in a bottle.

Thing to Consider

- Not compatible with all materials

Bottom line

It is something we strongly suggest, especially if you’re having problems with warping. Although it is pricey, a little goes a long way and lasts a long time.

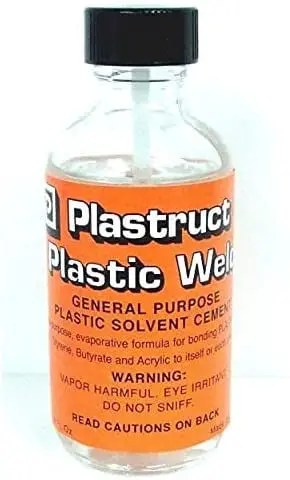

3. Plastruct Plastic Weld – Best For Multiple Surfaces

Buy on Amazon

Important Specifications

- Net Wt: 2 fl oz

- Bonds: Plastic

- Color: Clear

Product highlights

This stuff is fantastic. It’s similar to PVC pipe adhesive, but it’s a little thinner, like PVC pipe primer.

The definition “glue” or “adhesive” isn’t quite accurate for this. It’s a solvent that makes the PLA surface sticky, causing the parts to adhere together as if molded in that manner.

Put the parts together and then apply a “drop” of the solvent to the joint according to the instructions. It’ll wick its way into the joint.

There is a technique to keep the cracked or fractured pieces together without leaving gaps. Then apply the adhesive to one side and wait for it to cure, which should take less than a minute.

Turn it over and do the same thing on the other side. You are utilizing too much if it takes more than a minute. Allow it to sit for 5 to 10 minutes on its own. It does take some time to cure. Allow it to cure for at least one night.

However, you may be dissatisfied the first time you apply this product. It doesn’t connect the components in any way.

But go over the guide again; you’re bound to miss something, just as we did. When you finish reading the instructions, you’ll see the command: “Shake it up!”

Yes, before squeezing this solvent, give it a good shake. The fully set welds were substantially stronger the next day.

Please keep in mind that there are millions of different types of plastics, each of which requires a different type of adhesive. This one works with hard polymers commonly seen in consumer goods.

Because it is exceedingly thin and goes into cracks, it is simple to use. It’s not a filler for a hole.

Plastruct Plastic Weld was very simple to use and flowed beautifully into joints because of capillary action. It turns out that it smells no worse than regular Testors cement. However, you must do the task in your garage to protect the odor from entering the home.

Remember that this isn’t your average adhesive, and it’s rather runny. It comes with a little built-in brush, which we appreciate. The only major drawback is that the brush with the bottle is fairly large.

Furthermore, the product soon degrades. As a result, it’s critical to screw on the cap as quickly as possible after you’re finished.

What We Like

- Solvent melt plastic surfaces

- Built-in brush for application

- Lid with anti-clogging properties

- Simple to use

- Reasonable cost

Thing to Consider

- Unpleasant smell

- Not work with hard polymers

Bottom line

Plastruct Plastic Weld will be your go-to adhesive for PLA miniatures, PLA repairs around the house, and PLA vehicles.

It softens and melts the PLA to make it operate. So that you may reassemble the components, it is simple to use and works quickly.

4. Glue Masters Professional Grade CA – Best For Budget

Buy on Amazon

Important Specifications

- Net Wt: 2 oz

- Bonds: Wood, plastic, fabric

- Color: Clear

Product highlights

Gorilla super glue has always been our go-to adhesive. But, we decided to give this glue a try after reading the reviews.

You’re receiving a product of a cyanoacrylate-based adhesive that’s stronger than super glue but safer. It has a greater viscosity and is less watery.

The bottle does not clog or jam, obviously important for long-term product use. It’s one of the most effective CA adhesives on the market.

Because a drop of superglue in your eye is three drops too much, it’s just around a drop. When you sit down, wear glasses or be aware of this and look aside.

A tiny spray of mist or a pinch of baking soda can also help it set quickly. Baking soda may create a polymer that can fill microscopic holes and gaps.

The viscosity of the medium viscosity is thin at room temperature and medium in the refrigerator. Unless you use one of the accelerators, it takes nearly twice as long to set after taking it from the fridge.

Then cover it with something heavy or tape, so the glue doesn’t attach to anything other than what it’s meant to stick to. It’s a lot less work than the Gorilla super glue gel we’ve been attempting to use.

It dried in a matter of seconds, and the louvers were firmly in place. One customer said he left a 3D-printed model made of PLA outside. It withstood rain, cold, and a lack of wind, and the bond is still tight.

What We Like

- Wide range of application surfaces

- Strong bond

- Anti-clogged lid

- Economic design

- Greater viscosity

- Less watery

- Rain and cold resistance

Thing to Consider

- Unpleasant odor

- Bonds skin instantly

Bottom line

Using the pointed tip at the end of the container, we found this adhesive to be simple to apply. The PLA glue had a perfect consistency and did not run or extend beyond the application area.

You may use the bottle at any time because it is clean and jam-free. It may be the greatest money you’ve ever spent!

5. MITREAPEL Super CA Glue – Best For Robust Joints

Buy on Amazon

Important Specifications

- Net Wt: 3.3 fl oz and 0.8 oz.

- Bonds: Wood, fiberglass, glass, leather, ceramic, plastic, metal, rubber

- Color: Clear

Product highlights

This product comes in two separate containers and is effective and simple. When the adhesive and the activator make contact, it dries very instantly!

The speed with which this method adheres pieces together will astound you. Because there is almost no adjusting time, you must ensure aligning all pieces exactly where they need to be.

It is the greatest superglue you’ll ever use. We 3D print PLA miniatures that require assembly on occasion. And finding an adhesive that joins PLA to PLA rapidly and successfully has been tough.

We tried well-known brands like Gorilla and Krazy glue, which took an eternity to dry and resulted in weak bonding. With the spray, this stuff bonds quite nicely and swiftly.

It is the first time we’ve used a CA adhesive with a spray adhesive activator, which increases the glue’s stickiness, which we appreciate. We were fortunate that the parts were almost precisely aligned when we placed them together, and they were attached right away.

Be careful not to wind up with a misaligned joint if you use this. It forms a very robust joint once glued.

It grabs fast, has a long-lasting adhesive, and is attached metal to PLA like a wood glue connecting wood to wood. That’s it, as though they’re made of the same material and have merged into one solid piece.

It was as good as new in less than 30 seconds. It is a fantastic value, and there are plenty of activators left over for another bottle of CA.

You can learn more about other uses of MITREAPEL glue in the video below:

What We Like

- Compatible with a wide range of materials.

- It’s simple to use.

- Can remove excess adhesive.

- Curing time is short.

- It’s both water- and impact-resistant.

- Bonds quite nicely and swiftly

- Create robust joints

- Long-lasting adhesive

Thing to Consider

- Not suitable for outdoor use.

Bottom line

The first time we used this adhesive, it worked quite well. It cures in a matter of seconds and becomes very powerful. The thing performed just as you were supposed to. The fix went off without a hitch, just as we had planned.

Buying Guide For Best Glue For PLA

There are several factors to consider when deciding which adhesive to use. Before you go out and buy your adhesive, consider the following points.

Type Of Adhesive

Cyanoacrylate adhesive:

Cyanoacrylate adhesive is a type of adhesive that can hold things together. When gluing PLA pieces, cyanoacrylate glue is typically the best option.

Bonding PLA parts with cyanoacrylate or superglue is the best solution for most projects. It’s a quick-drying adhesive that’s simple to apply.

You may get outstanding results, a strong connection, and a nearly undetectable seam. Because it dries in seconds, think twice before using it!

Gorilla glue, Loctite, SuperGlue, extra-strong adhesive, or any fast glue will work. We prefer it in little tubes to not go bad if we don’t use it for a long time.

Epoxy:

If you choose to glue PLA parts together using epoxy, you will gain three additional benefits:

- You’ll obtain a better bond than you would with regular adhesive.

- If the two bonding surfaces are not level enough, you can fill tiny gaps.

- With the epoxy smoothing technique, you may also use epoxy resin to increase the surface quality. To eliminate 3D printing layer markings, apply an external layer to the component.

Hot glue:

A hot glue gun is an indispensable piece of equipment in every workshop. You may use it to make rapid joints, fill gaps, adhere to cardboard, and insulate electrical components.

It’s possible to use hot melt adhesive to adhere to PLA. When PLA hits 45-60 degrees Celsius, it softens, and you must be careful not to melt or damage the component.

Acetone:

Using acetone to glue PLA is an experimental method. Although acetone does not smooth PLA, it softens the exterior layer, gluing two components together.

Acetone or paint thinner may bond PLA components together. Any acetone-soluble substance, in other words, is an excellent option. This gluing method produces a very strong connection and an undetectable seam.

Product Flexibility

Different glue kinds have varying degrees of elasticity.

Some are more solid, like superglue, while others allow for some movement of the various pieces of your 3D creation. Think about the ultimate product’s function and desired aesthetic when considering flexibility.

Drying Time

The time it takes for the glue to cure varies. Some will take hours or days with clamps. If you can’t fasten your 3D model or don’t have clamps, you’ll need glue with a faster drying time. The best adhesive for PLA is one that dries quickly.

Temperature Of Glue

When some glues cure, they become hot. PLA plastics are heat sensitive, and at certain temperatures created during the curing process, they may begin to alter the shape, soften, or melt.

Glues can also react with certain chemicals, marking your creation or even burning through the PLA itself.

Appearance

Some glues leave a noticeable residue, while others require just a few centimeters of glue to operate well.

It is crucial when deciding which adhesive to use since it may alter your design in ways that aren’t aesthetically pleasing and detract from the overall appearance. PLA adhesive that is transparent and flawless is the best.

FAQs

Does Epoxy Resin Works Best For Gluing PLA?

Epoxy resin is the finest adhesive for porcelain or ceramic repairs if a project requires gap bonding, filling surface repairs, or laminating.

The epoxy resin consists of two components: resin and hardener. When combined, they form a long-lasting, high-strength bond.

Does PVA Glue Stick To PLA?

The standard PVA glue works well on PLA plastic items, and you can apply it with a paintbrush to achieve a comparable consistency.

A Step-by-Step Guide

Dry all of the pieces.

Apply a thin layer of ceramic adhesive on both sides of the shattered ceramic.

The manufacturer directed the bonded pieces back together and held them in place to cement the bond.

Once the adhesive has fully dried, remove any excess or spilled glue.

Can You Glue PLA With PVC Glue?

Super Glue and Gorilla Glue are strong, quick-drying adhesives that are simple to use. Glue Care recommends using them for thin and lightweight ceramics.

We successfully bonded a printed PLA part to PVC using Selleys All Plastic Fix adhesive. It’s a two-step process where you use a priming pen/marker to connect both pieces. Then, apply cyanoacrylate glue to one side and hold pressure on the joint for 30 seconds.

Is It Possible To Glue PLA Together With a Hot Glue Gun?

Yes, it’s possible to use a hot glue gun on PLA plastic. However, keep in mind that the glue must reach a particular temperature to melt, and it’s conceivable that your PLA will distort throughout the gluing process.

The hot glue gun is highly flexible and, depending on the manufacturer, might take a long time to cure.

Is It Possible To Melt PLA Using Acetone?

Although acetone will not melt pure PLA, you may use it as a solvent for PLA used in 3D printing. IT is due to various chemicals to the polymers used for printing, which are then impacted by the acetone.

Final Words

Finding the best glue for PLA won’t be difficult if you follow the guidelines above. You will now select your own choice and receive the repair outcome.

Let us know if you have any experience with the models in the ranking or if you know of any more fascinating representatives in the comments section.

Thank you for taking the time to read what we’ve written!

Related article: